Colour So Precise, It’s Microscopic

- Jul 29, 2025

- 6 min read

Author:

Ms. Dysha Cindrati, Marketing Manager, Alchemie Technology, Duxford, UK

With summer blooming into full colour, richly dyed textiles are everywhere, from vibrant swimwear to soft pastel linens that define the season’s mood. As the sun shines and wardrobes lighten, colour becomes more than a fashion statement; it's an expression of lifestyle, identity, and seasonal change.

But behind every vivid fabric lies a story often untold. It’s time to shed light on a hidden truth of traditional textile dyeing, an industry process that has long relied on immense amounts of water, energy, and chemicals to achieve the colours we love. What many consumers don’t realise is that their favourite summer shades may have left behind a trail of polluted rivers and carbon emissions. This isn’t just about better colour, it's about better choices for the planet. (More details on the impact of traditional textile dyeing on page 5.)

But seasonal shades do not need to be damaging. A new era of cleaner, smarter textile dyeing is here, replacing gallons of water with microscopic precision. At the heart of this transformation is digital dyeing technology: a revolutionary clean-tech solution that applies colour drop by drop with unrivalled accuracy and sustainability.

Summer Shades, Smarter Solutions

While traditional textile dyeing is as energy hungry as it is wasteful, the industry is witnessing a new horizon with a smarter solution. With sustainability becoming a core imperative across the textile supply chain, clean-tech innovations are stepping in to reimagine how colour is applied to fabrics. Among the most promising of these innovations is digital textile dyeing, a process that radically reduces water, chemical, and energy consumption by applying dye directly to the fabric surface with pinpoint accuracy.

Digital dyeing systems such as Alchemie’s are designed not only for precision but also for sustainability.

Alchemie’s digital dyeing technology enables:

A Comparison of Dye Application Methods

Modern digital dyeing technology builds on the foundational principles of inkjet printing but is engineered to overcome its limitations in textile applications.

Traditional inkjet systems

Eject picolitre-sized droplets (1 x 10⁻¹² litres), which rapidly lose momentum and are unable to penetrate fabrics, limiting them to surface-level printing and making them too costly for large-scale use.

Spray systems

Deliver a wide range of droplet sizes with variable momentum and direction. While they can reach fabric surfaces, they lack precision and control, resulting in limited applicability for consistent, high-quality dyeing.

Alchemie Technology

Alchemie’s solution bridges these gaps. Using nanolitre-sized droplets (1 x 10⁻⁹ litres), the technology maintains both high velocity and precise droplet control, ensuring deep fibre penetration with minimal waste. It operates without reliance on water or traditional energy infrastructure, supports electrification, and places no restrictions on dye chemistries or fabric types. Designed as a modular, end-to-end digital platform, it enables agile, low-inventory manufacturing aligned with modern, sustainable production environments.

One example of this shift is a high-speed dyeing platform that jets microscopic 10-micron droplets directly onto fabric. Unlike traditional methods that rely on heated water baths and long processing cycles, this system uses droplet momentum and placement accuracy to achieve uniform colour penetration, eliminating the need for post-treatment steps while dramatically reducing resource consumption.

This level of digital control makes it possible to apply colour sustainably, without depending on water-intensive methods. By combining precision application with process efficiency, the technology sets a new standard for scalable, clean textile dyeing.

Colour That Pops in Every Drop

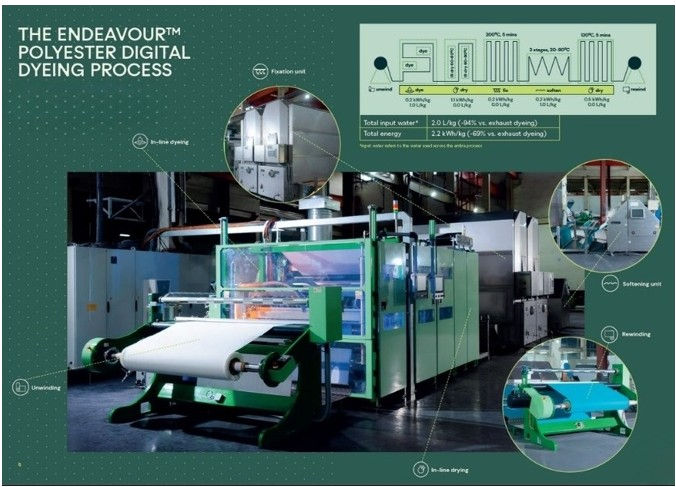

The Endeavour™ system enables industrial-scale digital dyeing with high-speed, precision droplet application. At the core of this system is a nozzle developed over more than a decade and manufactured to medical device quality standards. It uses a miniature 184 kHz piezoceramic dye applicator, capable of dispensing 270 million nanolitre droplets per second. Each droplet is just 10 microns in diameter, specifically designed to penetrate the textile and coat individual fibres.

This precise digital control allows for 10-micron registration accuracy, applying up to 1.2 billion dye droplets per linear metre of fabric. The result is consistent, deep colour saturation, minimal waste, and elimination of downstream processing steps such as soaping or reduction clearing.

This level of precision means no oversaturation, minimal excess dye, and no need for traditional downstream processes like reduction clearing or soaping, steps usually required to improve colour fastness in conventional methods. Endeavour™ achieves colour fastness ratings of ≥4/5 and maintains high chroma levels without post-treatment processes. The system is compatible with a wide range of commercially available dye chemistries, allowing for broad application across fabric types.

Alchemie’s technology is adaptable across multiple industry segments, from high-fashion and sportswear to home textiles and automotive interiors. For performance brands, the ability to control penetration and fastness ensures high durability and colour retention, even in extreme environments. For fast fashion and lifestyle retailers, the system offers a way to reduce inventory risk by enabling just-in-time production, while still delivering vibrant, quality colour. A lab-scale system, Discovery, is used to develop colour libraries by applying over 20 million droplets onto A5 fabric swatches, supporting formulation and process consistency.

Sustainable Summer Colours

As the fashion industry welcomes summer colours, it must also confront the environmental impact of traditional textile dyeing—a process responsible for enormous water consumption, energy use, and widespread chemical pollution. By switching to clean-tech systems like Alchemie’s Endeavour™, manufacturers can dramatically reduce their environmental and operational footprint.

As industries move toward net-zero targets, digital dyeing will play a pivotal role in transforming the environmental impact of fashion and textiles. With its minimal resource use and scalable implementation, technologies like Alchemie’s pave the way for a cleaner, faster, and more transparent manufacturing process. As regulation tightens—particularly in the EU and US—brands that fail to adopt cleaner processes will face greater compliance challenges. Early adopters, meanwhile, will gain a competitive edge by offering sustainably dyed products that resonate with environmentally conscious consumers.

Get in touch with us at enquiries@alchemietechnology.com to learn how you can implement Alchemie’s technology in your production line.

Hot Days, Polluted Waterways

The Legacy of Traditional Textile Dyeing

The art of dyeing textiles dates back thousands of years, with early civilisations in Egypt, India, and China using plant based dyes to colour natural fibres like cotton, wool, and silk. While these early methods were largely sustainable and biodegradable, the industrial revolution introduced synthetic dyes and mechanised processes that drastically increased environmental impact. Today, over 90% of global dye production relies on synthetic methods, many of which involve toxic compounds and non-biodegradable waste.

For as long as seasons have changed, traditional textile dyeing methods have been depriving water and energy sources. An estimated 5 trillion litres of water are used every year to dye fabrics alone. Using up to 150 litres per kilogram of fabric. In traditional textile dyeing, this must be heated often to 135°C, for both dyeing and rinsing cycles. These processes demand immense energy, typically from sources such as fossil fuels, to generate the necessary steam for certain fabrics.

As a result, traditional textile dyeing methods equate to 10% of global greenhouse gas emissions. If no action is taken, the textile industry will contribute more than 2.5 gigatons of CO2 before 2050.

Unfortunately, the environmental damage does not stop there. Both pre-treatment and post-dyeing processes, such as washing and reduction clearing are major contributors to pollution. When the water has been mixed with industry dyes, it produces wastewater that is discharged untreated, often containing unused dyes, fixatives, and toxic chemicals that contaminate ecosystems.

Textile dyeing is estimated to account for 20% of global industrial wastewater, with a single load of polyester clothing releasing up to 700,000 microplastic fibres into waterways. This means that, regardless of the season—even on the hottest days—textile dyeing continues to pollute our water systems.

The consequences of water and chemical pollution aren’t confined to ecosystems—they also affect the people who live near manufacturing hubs. In regions like Dhaka, Bangladesh or Tirupur, India, textile effluents have contaminated rivers and groundwater, impacting both human health and livelihoods. For fashion brands, the social and environmental cost of dyeing has become a reputational risk. As consumers demand transparency, brands are being held accountable for the impact of their supply chains. Clean, ethical colouration is no longer a niche, it is a necessity.

Digital technologies Will Expand Horizons

Digital technologies also offer many new possibilities for the textile and apparel industries to improve production processes, thus increasing efficiency, sustainability, product quality, and profitability.

Contact us at enquiries@alchemietechnology.com to explore new opportunities to implement digital technologies in your production systems.

Alchemie Technology Ltd.

The Flight Sergeants Mess

Duxford Business Park, Hurdles Way

Duxford, Cambridge, CB22 4PA, UK

Phone: +44 1223 751644

Web Site: https://www.alchemietechnology.com

What a detailed look into how precision and sustainability are redefining colour in textiles. Really makes you think about what goes on behind designs we take for granted. If you’re trying to present yourself just as meaningfully — say for job applications in Kuwait , Professional CV writers Kuwait can help make your story visible to employers by crafting documents that reflect who you are and what you value.